Biochar is a carbon-rich material derived from biomass that offers various environmental and agricultural benefits. To facilitate the production of biochar, mobile biochar machines have emerged as a convenient and efficient solution. In this article, we will explore five key advantages of utilizing a mobile biochar machine.

NO.1 Portability and Flexibility

Compact size and lightweight design

The mobile biochar machines are designed with a compact size and lightweight structure, which ensures their portability and ease of use. This feature allows for convenient transportation and deployment in diverse locations.

Ease of transportation to remote locations

Due to their compactness and lightweight design, mobile biochar machines can be easily transported to remote locations, including rural areas or disaster-stricken regions. This mobility enables on-site processing of biomass resources, eliminating the need for costly and time-consuming transportation.

Ability to process biomass on-site

Mobile biochar machines provide the advantage of on-site processing. They can efficiently convert biomass into biochar right at the source, reducing logistical challenges and enhancing overall operational efficiency.

NO.2 Increased Efficiency and Productivity

Continuous operation and high processing capacity

Mobile biochar machines are designed for continuous operation, ensuring a consistent production process. Their high processing capacity allows for efficient and uninterrupted biochar production, meeting the growing demand for sustainable soil amendment solutions.

Reduced downtime and increased productivity

With their continuous operation capability, biochar pyrolysis equipment experiences reduced downtime. This leads to increased productivity and a higher output of biochar, ultimately improving the overall efficiency of the production process.

Multiple feedstock options for biochar production

Mobile biochar machines offer the flexibility to process various types of biomass feedstocks. This versatility allows for the utilization of different agricultural residues, forestry waste, or organic by-products, maximizing the potential for biochar production and resource utilization.

NO.3 Environmental Benefits

Reduction of greenhouse gas emissions

The production of biochar through mobile machines contributes to the reduction of greenhouse gas emissions. The pyrolysis process used in these machines prevents the release of carbon dioxide into the atmosphere, offering an environmentally friendly alternative for biochar production.

Preservation of soil fertility and nutrient retention

Adding biochar to the soil enhances its fertility by improving water retention, nutrient availability, and microbial activity. The porous structure of biochar acts as a reservoir, reducing nutrient leaching and promoting long-term soil health, thus preserving the natural fertility of the soil.

Mitigation of waste disposal issues

Biomass pyrolysis plants play a crucial role in waste management by effectively converting biomass waste streams into valuable biochar. This mitigates waste disposal issues, providing a sustainable solution to the growing problem of organic waste accumulation.

NO.4 Cost Savings and Economic Viability

Elimination of transportation costs

By enabling on-site processing, mobile biochar machines eliminate the need for long-distance transportation of biomass materials. This results in significant cost savings associated with transportation, making biochar production more economically viable.

Generation of additional revenue streams

In addition to biochar, mobile machines can generate revenue through by-products such as bio-oil and syngas. These by-products have diverse applications, including energy generation, creating additional revenue streams and enhancing the economic viability of mobile biochar machines.

Lower investment and operational costs

Compared to larger-scale biochar production facilities, mobile biochar machines require lower initial investment and operational costs. This affordability makes them accessible to small-scale farmers, community groups, and entrepreneurs interested in biochar production.

NO.5 Versatility and Adaptability

Ability to produce biochar from various feedstocks

Mobile biochar machines offer the ability to process a wide range of feedstocks. They can convert agricultural waste, forestry residues, and organic by-products into biochar, utilizing locally available biomass resources and maximizing biochar production potential.

Integration with existing systems and processes

Mobile biochar machines can be easily integrated with existing agricultural or industrial systems. They can utilize waste heat from other processes or incorporate excess biomass from farming activities, enhancing overall system efficiency and resource utilization.

Potential for diversified applications

Beyond soil enhancement, biochar produced by mobile machines has potential applications in various fields. It can be used for filtration purposes, carbon sequestration, or as a component in sustainable construction materials. This versatility allows for diversified applications, expanding the opportunities for biochar utilization.

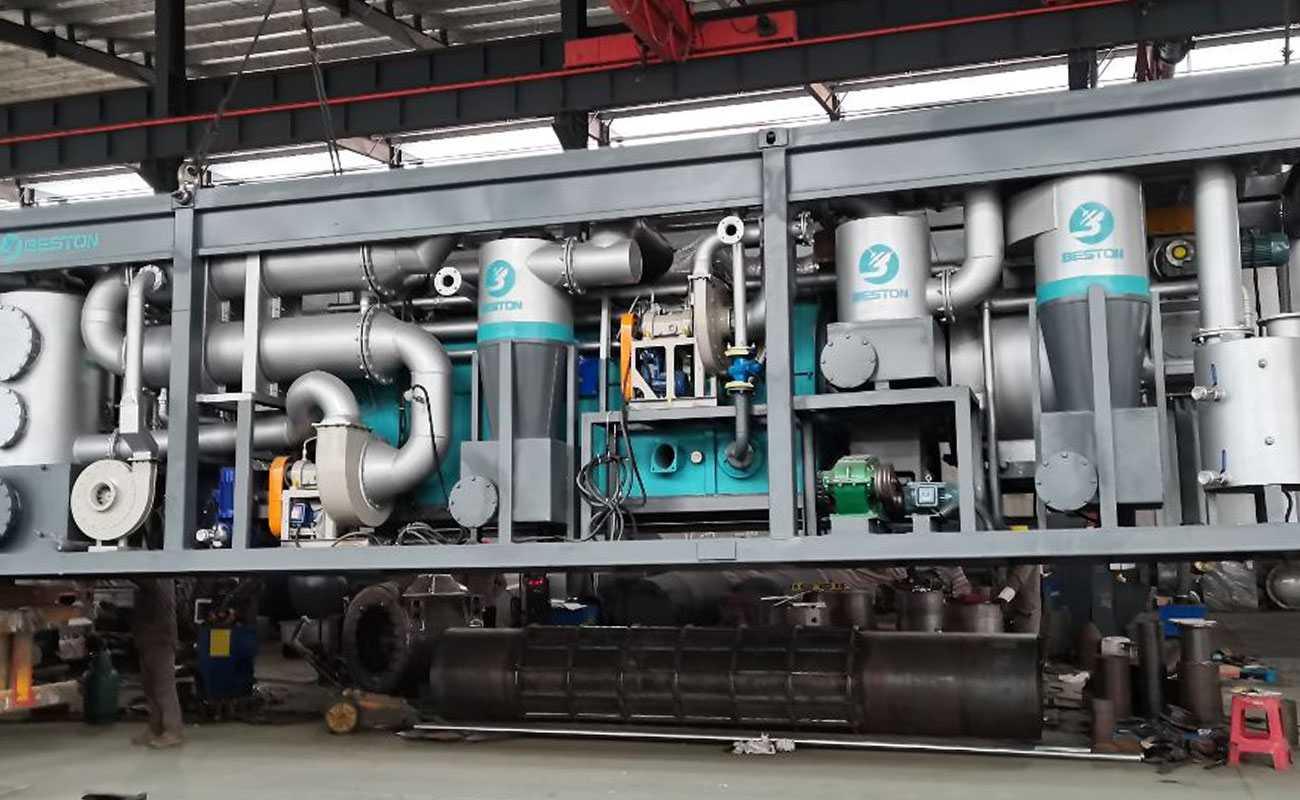

If you are looking for a manufacturer of reliable biochar machines, we recommend Beston Group as your first choice.

Conclusion

Mobile biochar machines offer several advantages for biochar production. Their portability and flexibility enable on-site processing, increasing efficiency and reducing transportation costs. Furthermore, these machines provide significant environmental benefits, including the reduction of greenhouse gas emissions and mitigation of waste disposal issues. They also offer cost savings and economic viability, generating additional revenue streams while remaining accessible to smaller-scale operations. With their versatility and adaptability, mobile biochar machines unlock opportunities for sustainable resource utilization and diversified applications. Embracing this technology can pave the way for a greener and more sustainable future.