At present, many people concerns waste tyre recycling plant cost. These days, regardless of whether we are talking about developed or developing counties, increasing numbers of people are choosing to buy cars due to cheaper worldwide vehicle prices and improved economic ability. As a result, the quantity of scrap tires waiting for disposal has increased significantly. On a global scale, more than 3 billion rubber tires are dumped annually. In the United States, tires are discarded at a rate of over one tire per person per year, equating to over 300 million scrap tires annually. The tire disposal rates in other first world countries are not much better. In Canada, for instance, around 26 million tires are sent to landfill sites each year. In China, each year, over ten million car tires are scrapped. The world’s largest tire graveyard can be found in Kuwait. If you are searching for a fair tyre recycling plant cost, why don’t visit Beston?

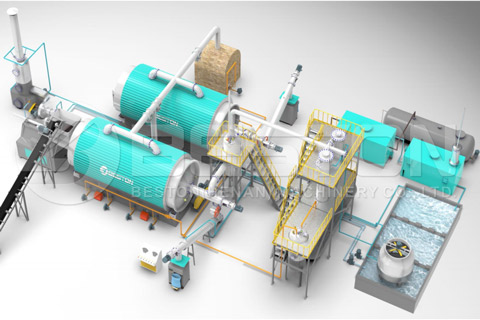

Fortunately, there have been many advances in recycling technology over the years, and it is now possible to avail of tire to oil machines. These machines are capable of converting waste tires into fuel oil via the pyrolysis process. One of the best things about such machines is that they produce no pollution and are incredibly energy efficient. When it comes to determining the cost of waste tyre pyrolysis plant, the type of rubber pyrolysis reactor that you choose will have the biggest impact on the price.

If you are looking to run the most productive tire recycling business, you need to source continuous pyrolysis reactor plants with high automation levels. If, however, you only need to process a few tons of tires each week, you might want to look at batch system plants. Batch waste tire pyrolysis reactor plants are much more affordable, but they have lower hourly processing rates, and the reactor has to be cooled down between batches.

When you consider the end products that are output from a scrap tire pyrolysis machine, you will understand there is a lot of money to be made in the tire recycling business. Those end products are fuel oil, carbon black, steel wires, and combustible gases. The combustible gases are typically sent back through the system to reheat the reactor and reduce plant energy costs. The fuel oil can be sold for reasonable sums in its raw state, or it can be refined into gasoline or diesel oil using a distillation machine. The carbon black can be sold to many different industries, while the steel wires are generally sold directly to metal refineries. There is a related blog for you to see: https://bestoncarbonizing.blog.fc2blog.us/.

As more and more recycling firms embrace the lastest pyrolysis technology, it is likely that the average waste tyre recycling plant cost will decrease considerably. You can already avail of more affordable prices on tire to oil machines by contacting overseas manufacturers. Most industrial tire processing plant equipment manufacturers are able to export their products all over the world. You can contact them via email or phone to request an estimate. However, it’s important to take time to determine the needs of your scrap tire processing business before you start comparing tire to oil machines from different brands. Review https://BestonTurkey.com/ to see Beston.