In the past, many different types of agricultural waste, such as palm kernel shells, sawdust, bamboo, rice hulls, and peanut shells, were simply used as livestock feed or burnt for heat. In recent decades, however, advancements in carbonization technology have meant that it is now possible to turn biomass waste into bio charcoal fuel. You will find many different charcoal maker designs for carbonization machines in the marketplace, but they are all capable of converting biomass waste into biochar via a process that produces no toxic emissions.

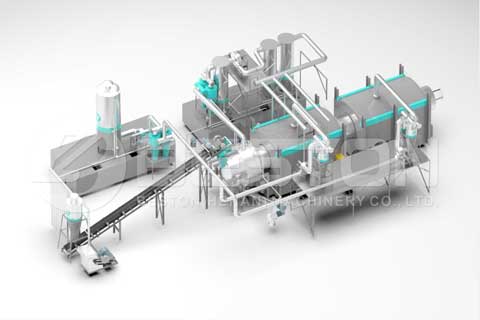

Biochar making machines are starting to become much more affordable and you will now see them in recycling waste management facilities around the globe. In fact, investing in such a biomass carbonization plant can be a very profitable business venture. When it comes to prolific manufacturers in the industry, Beston Group is arguable the leading player. The company sells a wide range of carbonization furnaces that are compatible with all sorts of biomass waste, including agricultural waste, municipal waste, and oil sludge waste.

To explain further how biomass carbonization works, let’s consider how palm kernel shells are converted into biochar. To begin with, the shells need to be crushed into small, evenly size particles. Next, if the moisture content of the palm kernel shells exceeds around 15%, drying processes are required. This is because if there is too much water in the biomass waste, carbonization will be inefficient due to the production of large amounts of steam. For high-grade bio charcoal production, the palm kernel shells should be as dry as possible.

Once the waste has been prepped, a conveyor belt system of the palm kernel shell charcoal machine transports it into the carbonization reactor. The reactor furnace heats the palm kernel shell waste to very high temperatures resulting in the production of biogas and biochar. The reason why biogas and biochar are produced rather than smoke, heat, and ash is that the carbonization reactor is an oxygen-free environment. All of the biogas produced during the carbonization process is typically used to refuel the furnace and establish an almost self-perpetuating process, resulting in reducing running costs.

To meet the high emissions standards set by many governing bodies around the world, such as the EU, modern bio charcoal maker designs include advanced dedusting systems. Advanced dedusting systems clean all emissions so that no toxic components are released into the atmosphere.

When it comes to comparing different bio charcoal making machines for sale online, there is a wide range of factors to take into account. Some key specs to compare include hourly feeding capacity, raw material compatibility, operating pressure, life span, total power, reactor size, working method, cooling method, and price.

Please go to the following website if you want to purchase this kind of machine to get palm kernel shell charcoal: https://bestonmalaysia.com/.