The Benefits of a Scrap Tyre Pyrolysis Plant

Before you choose a scrap tyre pyrolysis system, you must understand what it is capable of. This article will discuss the different types of pyrolysis systems and their respective benefits. You will also learn about the different types of processes, including carbon black, batch type, and semi-continuous. Once you understand what this process can do for your company, you can make an informed decision.

Carbon Black

Using a waste tire pyrolysis plant(planta pirolisis neumaticos), you can convert waste tire oils into carbon black, a valuable feedstock for rubber, paint, ink, and toner manufacturers. While there are already a number of tire pyrolysis plants in operation, their economics are generally poor because of the value of their end products. Increasing the value of waste tires can improve economic leverage by making them more valuable.

A tire pyrolysis plant produces two main products, a refractory carbon black and a liquid fuel. The former can be sold directly to the market, but is generally further processed before being sold. The two main further processing steps involve grinding or briquetting. The carbon black produced is about 40 mesh in size, which makes it suitable as a fuel in industrial heating facilities.

Batch type

There are several types of pyrolysis plants(planta de reciclaje de neumaticos). Some of these plants can process up to 10 tons of raw material per day, while others are capable of processing eight to ten tons of material per day. These types of plants are known as batch type and are used to process waste plastics. In addition to oil and carbon black, the waste plastics can also be recycled for other uses, including steel wire. These materials are then used in many industries.

There are many differences between batch and continuous types of tire pyrolysis plants. Continuous types need to have a small hole to feed the raw materials. They also need a shredder machine to cut the waste tyre. Batch types are different because waste tires are fed directly into the reactor, while continuous types need to be manually fed. Batch types also have the added advantage of being more efficient since they can use the waste tires without the hassle of removing the wires.

Semi-continuous

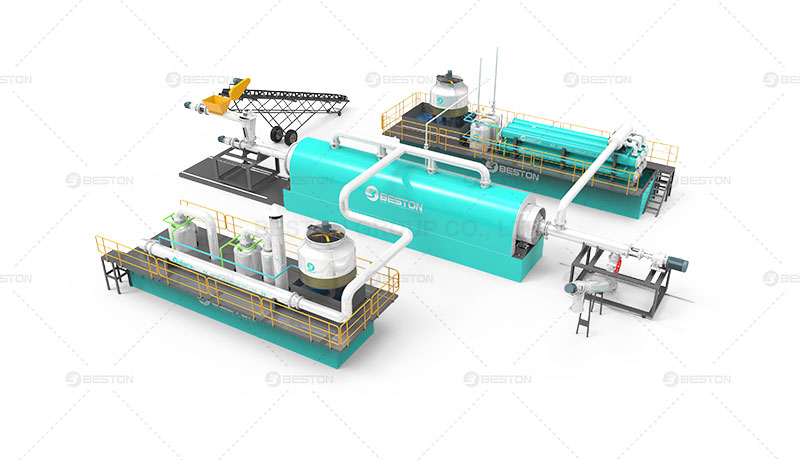

The semi-continuous scrap tyre pyrolysis plant has a rotary reactor and screw automatic feeders. These feeders move the broken tires into the reactor chamber and prevent air from entering the closed system. In addition, semi-continuous pyrolysis plants are easy to operate and require little labor. They also produce less dust. These plants can run three or four shifts a day.

Beston has a wide variety of pyrolysis reactors and offers a manufacturer’s guarantee. This is an important feature as the workers are not exposed to any harmful gas when operating the plant. Beston pyrolysis reactors can be installed in different configurations to meet specific customer requirements. The pyrolysis process of scrap tires can be used to create gasoline or diesel. The process is also beneficial for heavy industries like steel factories, iron factories, boilers, and ceramics.

A fully-continuous tyre pyrolysis plant(https://www.bestoneco.com/lj-3-enviado-a-paraguay/) is a high-capacity plant that has a high production rate. With continuous operation, a company can process up to 24 tons of waste tyres a day. Both types have a 360-degree rotary reactor design. However, the continuous unit has a horizontal reactor design, making it more stable. In addition to this, a fully-continuous tire pyrolysis plant can be run 24 hours a day.

Cost

The cost of waste tire pyrolysis plant has come down in recent years because technology has improved. Fully automated waste tire pyrolysis plants are available for very little cost. They turn scrap tires into lubricants and fuels that are more useful than they were before. The end products are used for various purposes, including transportation, construction, and landscaping.

The cost of a tire pyrolysis plant(beston eco grupo) will depend on its size and functionality. It should be large enough to recycle waste tire materials. There are also many auxiliary components that can be included in a waste tire pyrolysis plant. You should consider all these aspects when calculating the cost of a scrap tire pyrolysis plant.

There are various options available, and choosing the right one will depend on your specific needs. The basic configuration of a tire pyrolysis plant is suitable for regions with lower labor costs and environmental protection. However, if you plan to operate your scrap tire pyrolysis plant in a highly regulated environment, you should opt for a high-configuration machine.