When you are able to convert organic materials into burnable fuel, this occurs because of the pyrolysis process. There are small machines, and entire plants, designed for this express purpose. The cost of each one of these can vary. The smaller the system, the more affordable it is going to be. You can also save money by obtaining one from a larger business that simply sells them for less. If you would like to save as much as you can on a pyrolysis plant, this is how you can reduce pyrolysis plant cost.

The Cost Of Pyrolysis Plants Today

Depending upon the currency that you use, and the location of the pyrolysis plant, you can save a considerable amount on your investment. If you were to purchase one in China, India, or a variety of other countries that can make these for less, this is how you can save the most when you get pyrolysis machine for sale. These can cost six figures or more depending upon their size. You need to consider the type of output that is possible. A larger system, such as a pyrolysis plant, can be expensive but can also be your biggest supplier of charcoal.

How The Conversion Process Occurs

The conversion of plastic, rice husks, or even rubber tires, is possible with these systems. They will often have a very large reactor where you can insert smaller pieces of these materials. You will want to have an ample supply of these materials or a consistent source for them to make this work. By using them every day, you can easily pay for the initial investment by selling charcoal and other byproducts. The conversion itself occurs because of heat. Within the reactor, it will begin to change at a chemical level. No oxygen is allowed into the chamber which will eliminate any of the materials combusting. Once you have a large stockpile, or if you are selling it every day, you will know that this decision is worthwhile. The last step is to look for the lowest possible pyrolysis plant cost to minimize your investment.

With The Cost Very Much To Get One?

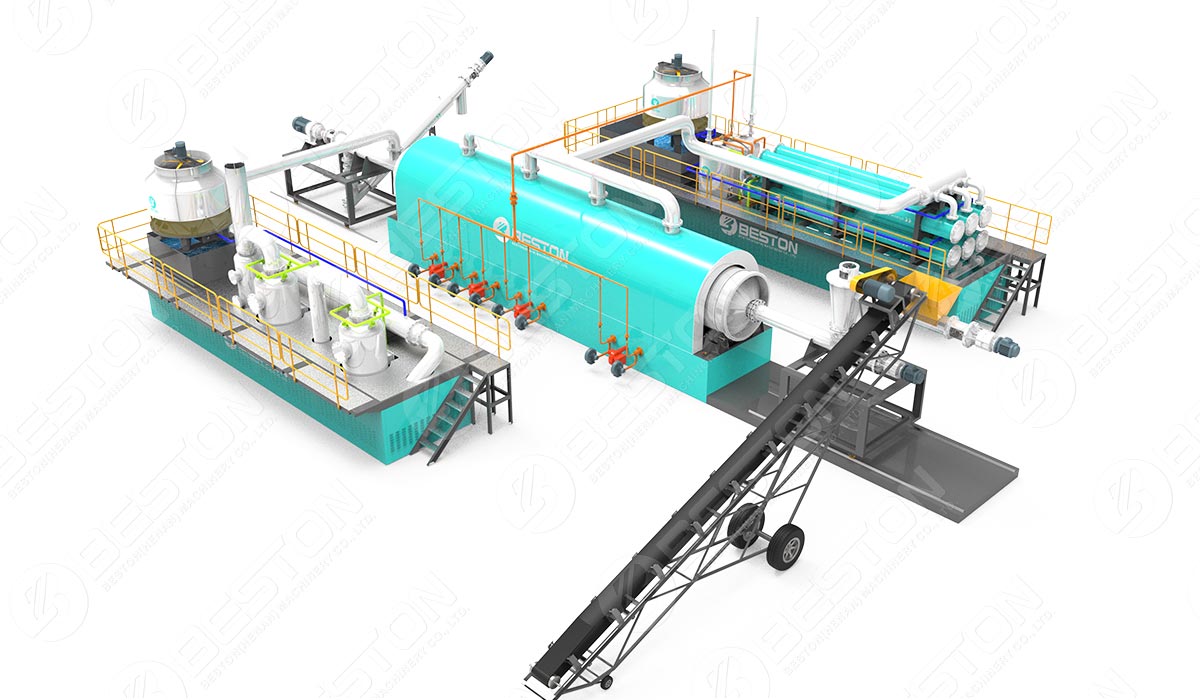

The amount that you pay is often based upon its overall size. For example, each of these systems will have multiple working components that help complete the process. There will be an oil tank, a continuous rotating pyrolysis reactor, and a continuous tyre pyrolysis plant for sale as well. If you are working with plastic, there is often a machine that can chip up the pieces into smaller components. Finally, the reactor that you order with your pyrolysis plant can be exceedingly large and very effective. The cost for all of this can be minimized as long as you’re willing to get as many estimates as possible.

The cost of a pyrolysis plant has gone up in recent years. Part of the reason has to do with the cost of labor and components. Despite the fact that many companies are not able to sell these for a reasonable cost, there are businesses you can find online. Companies that produce pyrolysis plants will often have them ready to ship. You will need to make sure you are paying a fair price. If used regularly, it could be a phenomenal way to generate additional revenue for your business. All it takes is finding a continuous tyre pyrolysis plant manufacturer that will sell these at a low price point.